Three Schemes for the Transformation of Industrial Router into Rural Power Network

With the rapid development trend of modern social science and technology, it promotes the development of the Internet and the development of the Internet of Things technology. Industrial routers in the field of Internet of Things technology give 5G/4G. It is necessary to build the remote control and detection system of rural power grid, which is also in line with the lean management requirements of power supply companies. How to build the Internet in places where metal is not available and places where metal is available.

1. Three schemes of industrial router Rural network transformation:

1. The industrial router connection network system software adopts GPRS wireless transmission technology to carry out real-time remote control detection and manipulation of the rural distribution transformers and their equipment operation and working conditions in the power supply jurisdiction, and complete the overall goal of unified detection and one-by-one manipulation from the monitoring station to each distribution transformer. In the communication mode, big data technology and wireless transmission technology are used to carry out rapid and reliable remote supervision.

2. The network system software of industrial router is mainly composed of the front control part, the wireless transmission part and the service platform part.

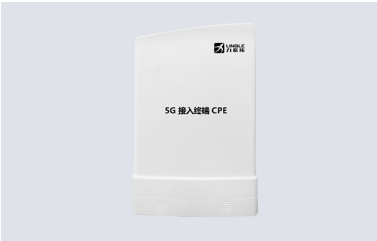

3.3G/4G/5G industrial router communication transmission equipment. According to the operator's 3G/4G/5Gwifi network will be real-time in front of the control system running status. Send the service platform control view command to the preceding machine device. Instant smooth point-to-point communication. Equal measures to reduce the probability of casualties in rural power grids. It can also use the data information of the service platform to grasp the electricity consumption of the rural power grid in real time. According to the regularity of the electricity consumption of the rural power grid, it can carry out the voltage change and volume adjustment in real time to improve the operation efficiency of the rural power grid.

If there are defects in the machinery and equipment, it can be timely dealt with and tracked, inspected and solved, which is of more practical significance to ensure the security of rural power grid. Early detection of problems and common faults can reduce the cycle time of rural power grid maintenance, and ensure that the maintenance work is problem-oriented according to the common fault data information. Because the new online detection technology checks all kinds of major parameters under the operating voltage and condition of power grid machines and equipment, the detection results are in line with the actual situation, and are more real and comprehensive. New maintenance items, content and time can be defined according to the rapid development and change of all kinds of data information. The maintenance goal is established and the purpose is stronger. Improve the power supply stability of machines and equipment. Because of the implementation of maintenance, it reduces the frequency and time of route power outage, improves the stability of power supply, prevents less power supply damage, and at the same time improves the labor efficiency of all personnel in electric power enterprises. Strict tests are carried out according to grounding resistance, compressive strength of insulation layer, impact of surge protector, electrostatic discharge interference, high and low temperature test, magnetic field of microwave radio-frequency radiation source, direct current electromagnetic field, etc.